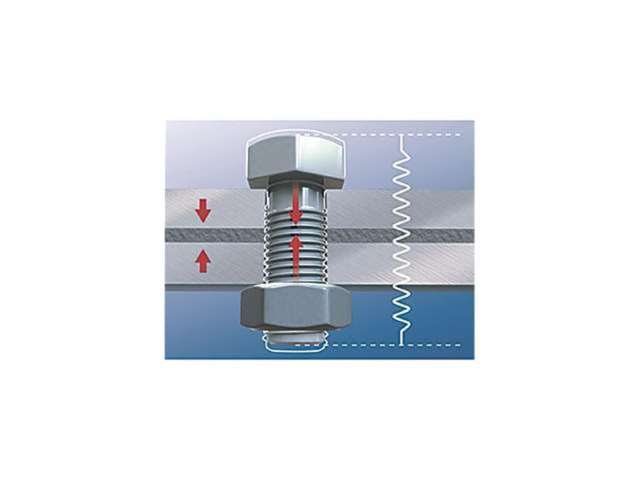

Why Do Bolted Joints Fail?

Bolted joints are one of the most common elements in construction and machine design yet most engineers have bolt problems at some point in their career. Use our BoltExpert wrap to understand joint mechanics and find solutions to fastener problems.

Ever found a bolt that is inexplicably loose or missing altogether? Few engineer have enough bolting knowledge to suggest corrective actions with confidence. Our BoltExpert Wrap will explain common practises like:

- Why we don’t like reusing bolts.

- Why there is no such thing as a standard torque.

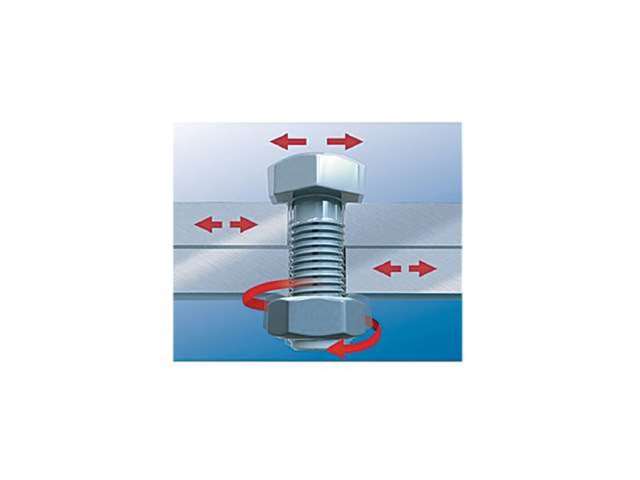

- Why one bolt comes loose whilst other seemingly identical bolts do not.

- Why some bolt tightening methods are better than others.

- What secondary locking devices can we trust (deformed thread, split pin, wire locking, double nut, Philidas nut, tab washer, nyloc, spring washers, loctite, Nord-lock washer…)

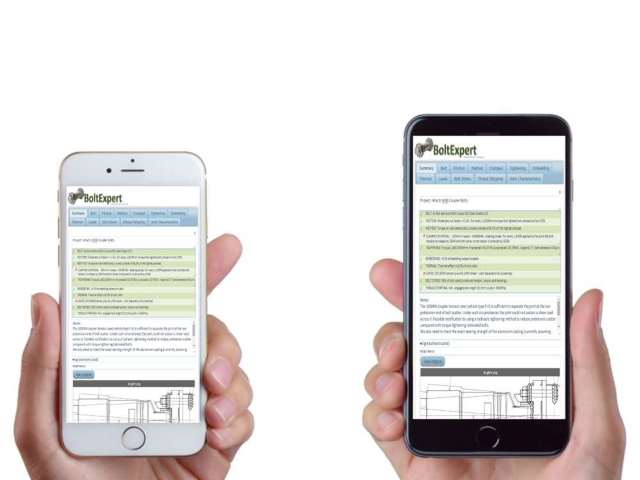

We use our BoltExpert Wrap both as a training tool and to help engineers understand joint mechanics. It works by considering each element of a bolted joint to reveal the root cause of loosening and the most effective corrective action. Using drop-down controls you can represent your own bolted joint, it will do all the complex maths and present results in live interactive charts. You are guided by integrated videos to explain both how to work the Wrap and to explain the physical phenomenon under consideration. It can be accessed by your PC, your tablet or your phone and each bolt you consider can be stored in a cloud database.